Copper Giant’s Mocoa Project Shows High Recovery Rates in Preliminary Metallurgical Tests

Copper Giant Resources Corp. (TSXV: CGNT, OTCQB: LBCMF, FRA: 29H0) has announced initial bench-scale metallurgical test results for its Mocoa copper-molybdenum project in Putumayo, Colombia. The preliminary findings indicate strong recoveries, with up to 92.3% for copper and 97.4% for molybdenum, which exceed the 90% copper and 75% molybdenum recovery assumptions currently used in the project’s resource model.

Figure 1 – Molybdenite liberation on sample (CNW Group/COPPER GIANT RESOURCES CORP.)

The test work, conducted and supervised by SGS del Perú S.A.C., an independent ISO/IEC 17025-accredited laboratory, represents the first phase of a comprehensive metallurgical program. This program aims to establish a conceptual processing flowsheet to support a future Preliminary Economic Assessment (PEA). The company cautions that these results are based on a single 130 kg composite sample and may not be representative of the entire deposit. Further variability and locked-cycle testing are required.

The metallurgical program involved a series of staged tests, including comminution, flotation, and mineralogical characterization, on a composite sample sourced from three drill holes.

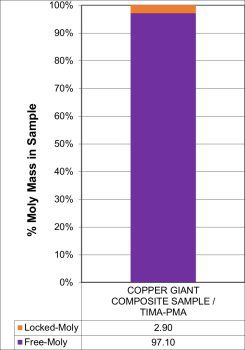

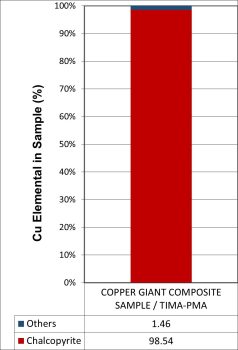

Mineralogical characterization confirmed that copper is predominantly hosted in chalcopyrite, a common and easily processed copper sulfide mineral. Molybdenum is present exclusively as molybdenite. Analysis using X-ray Diffraction (XRD) and a TESCAN Integrated Mineral Analyzer (TIMA-X) showed that minerals containing deleterious elements like arsenic were not detected in significant quantities, suggesting the potential for producing clean concentrates.

Liberation studies indicated that both chalcopyrite and molybdenite are effectively liberated at a relatively coarse grind size with a P80 (80% passing) of 150–180 micrometers (µm). At this grind size, 97% of the molybdenite was observed as free grains.

The flotation testing process was optimized for grind size, pH levels, and reagent suites.

Grind Size: A grind size of P80 150 µm was identified as the preferred condition, balancing recovery and processing costs. At this size, copper recovery reached 88.1% and molybdenum recovery was 96.2%.

pH Level: Tests conducted across a pH range of 9 to 11 showed robust flotation performance. A pH of 11 was selected as the base case for subsequent tests, yielding a copper recovery of 88.9%.

Reagent Optimization: The highest recoveries were achieved during reagent optimization tests. The addition of PAX (Potassium Amyl Xanthate) as a secondary collector (Test 01) resulted in a copper recovery of 92.2% and a molybdenum recovery of 97.4%.

Figure 2 – Copper-bearing mineral on sample. (CNW Group/COPPER GIANT RESOURCES CORP.)

The Mocoa project is situated approximately 10 kilometers from the town of Mocoa in southern Colombia. Copper Giant holds granted titles and applications for over 790 square kilometers in the region, which is part of the Jurassic porphyry belt, a geological formation that extends into Ecuador.

The deposit was first discovered in 1973 through a regional survey by the United Nations and the Colombian government. Subsequent exploration was carried out between 1978 and 1983, with additional drilling conducted by B2Gold Corp. (NYSE: BTG, TSX: BTO) in 2008 and 2012. The deposit remains open for expansion in all directions.

The results from this initial program will inform the design of the next phase of metallurgical testing. Copper Giant has outlined that future work will focus on developing an integrated flowsheet, optimizing regrind and reagent schemes to maximize recovery, and testing for concentrate quality and marketability. These advanced studies will provide the technical basis for a PEA.